The Top Reasons Why Helical Piers Are the Ultimate Foundation Repair Solution

A strong foundation is essential to the stability of any building, and when it comes to foundation repair,…

A strong foundation is essential to the stability of any building, and when it comes to foundation repair,…

Introduction When it comes to the foundation of your home, ensuring stability and durability is essential. Pier and…

The Infographic Are you confused about the difference between piles and piers? Do you find it challenging to…

Are you in the construction industry and wondering how many helical piles do i need for my next…

Real estate is a thriving industry, and there are numerous brokers across the United States who are making…

When it comes to building a solid foundation for any structure, there are two options that reign supreme:…

When it comes to construction projects that require the use of helical piers, finding the right contractor is…

Are you considering installing helical piers for your construction project but unsure of the best time of year…

When it comes to repairing a foundation that has started to show signs of damage, there are several…

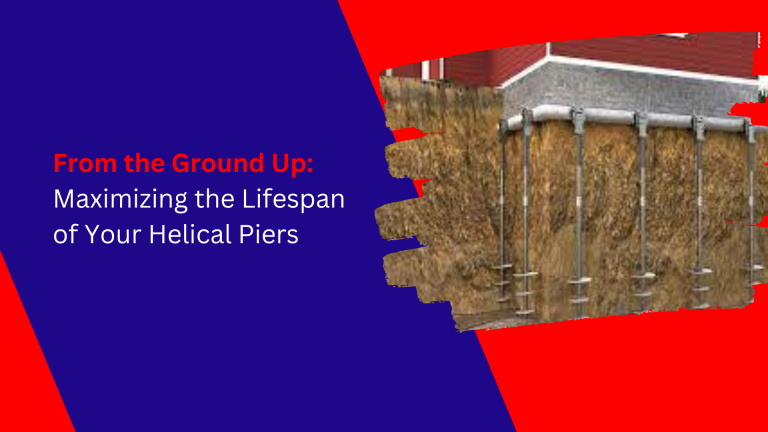

As a homeowner, you want to ensure that your property is built on a strong foundation that can…